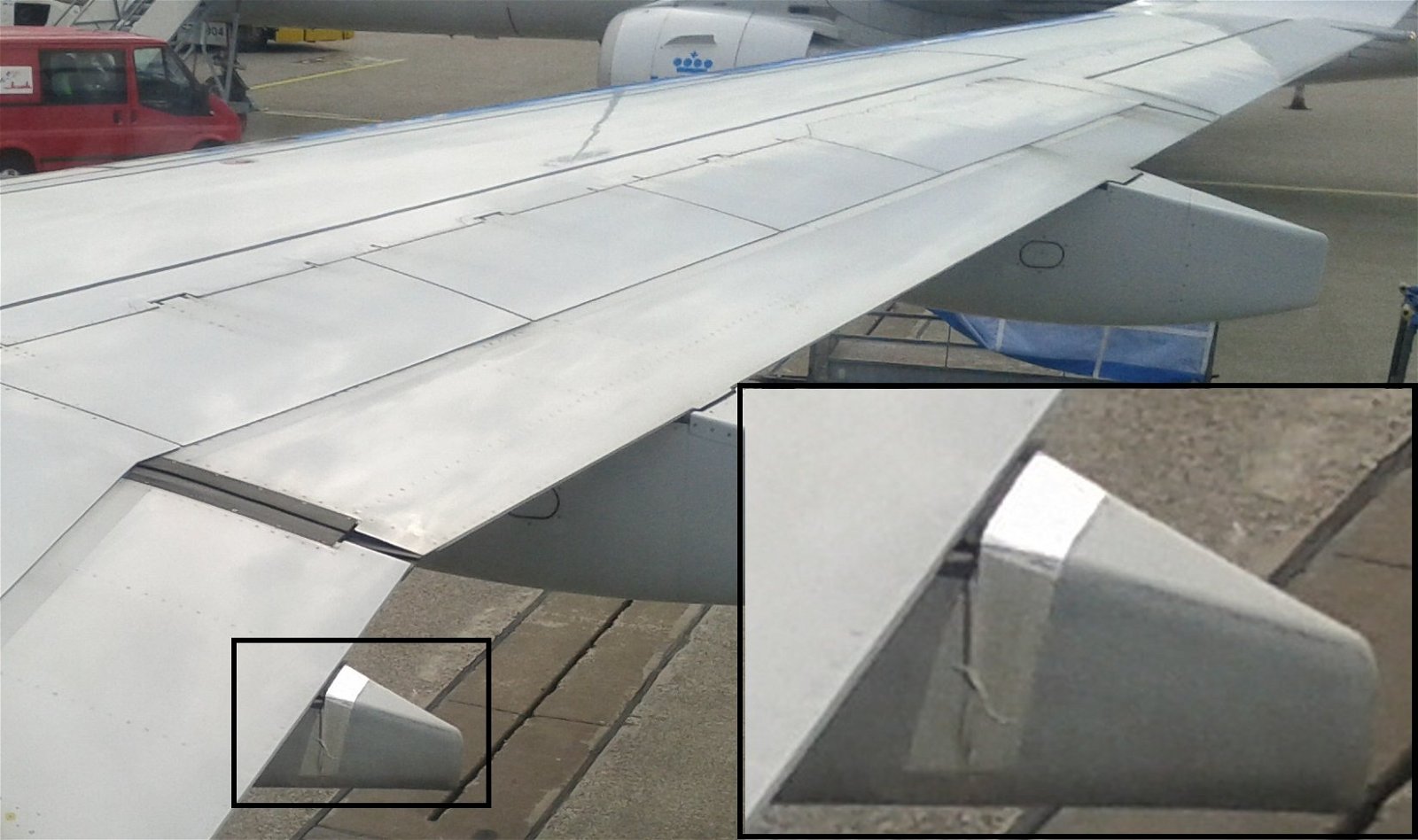

Occasionally I see panicked or appalled posts on social media where a passenger snaps a picture of something on their flight that appears to be held together with duct tape, usually accompanied by comments like, “How can this be safe!?” or “This plane is literally held together by duct tape – how reassuring.”

Years of personal experience have taught me that being an insufferable know-it-all isn’t the easiest way to win friends, so I typically won’t comment unless the passenger seems actually worried, in which case I just try to allay their fears.

The first thing to know (as I’m sure many of you avgeeks out there are fully aware) is that it’s not duct tape.

Speed tape, sometimes called aircraft tape or aluminum foil tape, is a special product that can withstand the high temperatures, moisture, wind, and other challenging conditions to which an aircraft fuselage is exposed during flight.

Although it bears a physical resemblance to the stuff you might use to patch holes in the upholstery of your ’89 Chevy Caprice, it’s actually much more resilient.

Aircraft tape is a fast, and temporary, fix for non-critical components

Mechanics and other aircraft experts widely regard speed tape as extremely safe when used properly. However, airlines must adhere to certain guidelines when using speed tape, lest they find themselves in a sticky situation with regulators. (Yes, that was two tape puns in one sentence. You’re welcome.)

Aluminum foil tape can be applied relatively quickly, and is only used for superficial issues. While durable, the idea is not to use speed tape as a permanent fix, rather it’s a temporary solution to keep the aircraft in service and the schedule on time until more extensive repairs can be completed. And rest assured, aircraft tape is applied by mechanics and maintenance teams — it’s not just a random member of the baggage crew slapping on some duct tape and calling it a day.

Bottom line

I do agree that an aircraft that appears to be composed of more tape than actual aluminum probably doesn’t put forth the best image. But I think most passengers would concede that a safe and temporary fix is acceptable when the alternative is a delayed or canceled flight.

In march i went to HongKong with Emirates in their first class and was very astonished to see some of the wooden panels in the shower spa held together with actual duct tape in a very slapdashy way. This was on the first lag from Vienna to Dubai in one of their older 380ies but i noticed the same thing on the second lag from DUB to HKG on a newer plane, noticeable by the...

In march i went to HongKong with Emirates in their first class and was very astonished to see some of the wooden panels in the shower spa held together with actual duct tape in a very slapdashy way. This was on the first lag from Vienna to Dubai in one of their older 380ies but i noticed the same thing on the second lag from DUB to HKG on a newer plane, noticeable by the bigger tablet like controlers in the suites.

I must admit i giggled but not in the way Lucky does when taking a shower in the Emirates 380.

Years ago I was on a flight where we were told there would be a delay in takeoff due to what was described as a “hole in the wing”! It seems that in the “walk around inspection before take off” it was discovered that there was a missing light lens which we were told would qualify as a hole and technically could ground us! Compounding the problem is the airport was not a hub for...

Years ago I was on a flight where we were told there would be a delay in takeoff due to what was described as a “hole in the wing”! It seems that in the “walk around inspection before take off” it was discovered that there was a missing light lens which we were told would qualify as a hole and technically could ground us! Compounding the problem is the airport was not a hub for the airline. I remember joking with passengers around me that what the needed was “man’s answer to any problem! Duct tape!” Oh course people laughed!

Moments later they pushed a service ladder up to the wing and we all watched intently. Two guys on the ladder solved the problem with what appeared to all— as a roll of duct tape! They neatly taped over the hole! We all chuckled and moments later we then took off. Was it duct tape? Well I can tell you that as we climbed into the sky, off it came! It was non essential and got us off the ground! I could not see them using the tape others described to fix what was clearly a temporary issue!

Well, my flight was delayed because of a technical issue, so I wouldn't mind if they had even used a duct tape haha. Now I have to fight for a compensation because I missed another flight (but a really great company, GIVT, is helping me right now with getting the money). Hope someday airlines will be more organised to avoid such events. Cause for a passenger it's super annoying!

Boos on the Grind!

Maybe it's time for America (and parts of Europe, hello BA/LH!) to not fly 20-30 year old planes that need to be patched together to be somewhat airworthy.

Most of us wouldn't want to drive a 30yr old car.

Great post, learnt something new today.

Speed tape is a marketing gimmick to mark up duct tape by 3,000%. It is duct tape. People need to appreciate duct tape more. This thing fixes from stone age tools till aerospace equipment.

I feel the need to repeat. When I was younger, I believed what I was told, that they were fuel tanks. But then I started paying attention to how planes are built, and they're clearly flap fairings.

That said, duct tape is nothing to scoff at. It'd probably good your plane together. Plus, it's not as expensive as something that has to be certified from -10 ASL @ -40C to 8000 feet @ 40C to FL 420@-60 C.

@AlohaDaveKennedy - those l, as noted above, house the systems that control the flaps. There are, as far as I know, no commercial aircraft operating with external fuel tanks. All fuel tanks are in the wings, horizontal stabilizer or belly of the aircraft.

@JamesP - I am not an airline mechanic, but I have held a roll of speed tape before and you would absolutely know the difference without even looking at it. Its tape...

@AlohaDaveKennedy - those l, as noted above, house the systems that control the flaps. There are, as far as I know, no commercial aircraft operating with external fuel tanks. All fuel tanks are in the wings, horizontal stabilizer or belly of the aircraft.

@JamesP - I am not an airline mechanic, but I have held a roll of speed tape before and you would absolutely know the difference without even looking at it. Its tape made out of aluminum. Feels and even looks very different than duct tape up close.

@AlohaDaveKennedy - Not, those are not fuel tanks at all. They are flap track fairings or anti-shock bodies.

I heard that not only is this tape extremely unique and strong. It is about $400 a roll. Like Kevin said it is used in non structural areas of the aircraft.

"Aircraft tape is a fast, and temporary, fix for non-critical components." Ummmm....isn't that a taped fuel tank in your photo? Since wing tanks are drained last are we supposed to believe that some fuel tanks are considered non-critical components?

JamesP: As someone who supported and worked closely with an airline’s Maintenance & Engineering group for several years, I disagree with your points. On the first, there are hundreds of parts on an aircraft that looks similar. In some cases the various rivets, screws, and washers may be 0.5 millimeter difference. This is why there are requirements around how parts must be stored and labeled. Looks at duct and speed tape side by side and...

JamesP: As someone who supported and worked closely with an airline’s Maintenance & Engineering group for several years, I disagree with your points. On the first, there are hundreds of parts on an aircraft that looks similar. In some cases the various rivets, screws, and washers may be 0.5 millimeter difference. This is why there are requirements around how parts must be stored and labeled. Looks at duct and speed tape side by side and you’d ha e to ha e vision issues to grab the wrong one. On the second, a technician puts their license at risk if they choose to do a repair not authorized or published in their company’s maintenance program. Technicians I’ve worked with don’t want that risk. Most carriers have quick approval processes for doing a non-standard repair to ensure it has a second opinion and make it easy for simple and non-critical items. Remember, even something with a probability of happening is no guarantee it will.

To the UA comment. They likely used the tape for a simple fix, issued a deferral to repair the issue at a set time, then went over that time or cycles.

Many exterior pieces of the aircraft exist only to improve aerodynamics and are 100% non-structural. These are called 'fairings', and the picture you have above is a fairing around the flap extension mechanism. That entire "box" could instead have been removed and the airplane would fly just fine.

I'm sure the stuff is great, but it's about appearances and images. We can blog and post about how it's normal to use for non-critical parts, etc. - that doesn't matter to the average (non-"AvGeek") passengers peering out the window of their plane.

There are two (operational) issues with this tape, that are beyond the "OMGI can't believe that that duct tap is what's keeping the plane in one piece". In my opinion, considering the risk involved, this is a no-brainer for anyone who have studied human factors and specifically the Normal Accident Theory (I know that this theory is not 100% supported by everyone, but I think that it definitely applies in this case).

1. The...

There are two (operational) issues with this tape, that are beyond the "OMGI can't believe that that duct tap is what's keeping the plane in one piece". In my opinion, considering the risk involved, this is a no-brainer for anyone who have studied human factors and specifically the Normal Accident Theory (I know that this theory is not 100% supported by everyone, but I think that it definitely applies in this case).

1. The resemblance of this tape to the duct tape we use can lead to an employee using duct tape by accident. I'm sure that there are specific procedures as for who can use it, how, approving its use, using on only certain components in certain cases, etc. - but the only two definite ways to avoid accidents in the future is either to ban regular duct tape in airports or stop using this kind of tape. Yes, this might be expensive and may call for additional expenses and IRROPS, but that's the way to go.

2. Although those procedures and redundancies exist, mechanical staff will most likely eventually use this tape to prevent fixing a malfunction in a way that this tape will not be the right solution. It all points there. It comes down to gaps in training, following procedures, human errors and modes of error that we (humankind and specifically whoever is involved in this industry) are not aware off. I know that many people will say "aviation is the safest way of transportation" (which is true) and "oh, aircraft mechanics must abide to so many rules so they can't get confused or whatever". But it's bound to happen.

While it is usually all quite SOP and within the rules, if I remember correctly some years ago UA was fined by the FAA for conducting 100+ flights with airplanes fixed by speed tape in an unauthorised way.

My friend's dad was a mechanic for one of the US3, and he brought a roll home to patch my friend's bumper when messed it up back in high school. Slapped it on, spray painted to match and off it went. Stuff is seriously heavy duty.

Mentour did a great VLOG on that topic:

https://www.youtube.com/watch?v=mG6gHpP6r1o